The plywood complies with EN 13501-1 and EN 13986 – classification in terms of reaction to fire B-s1, d0 (NON-FLAMMABLE).

We offer raw non-flammable P-certified birch and pine plywood, a FREP (Fire Retardant Ecologic Plywood) product. Spruce plywood in the process of certification.

The plywood is flame retardant throughout the cross section, not just on the surface.

The plywood is flame retarded in an advanced vacuum-pressure (deep) treatment process in an autoclave, using programmes specifically developed to work with the flame retardant Burnblock®.

More information regarding all FREP products will soon be available at www.plywoodfrep.com

It will be possible to obtain specially prepared packages, samples of our all certified (P) plywood products FREP, FREP L and FREP V&L.

Burnblock® is the sustainable choice for fire protection: a patented Danish flame retardant formula that is 100% non-toxic and biodegradable.

If sustainable and non-toxic fire protection is a priority for you, our P and Euroclass B certified FREP products are sure to catch your eye.

We are virtually the only manufacturer on the market to make no secret of the type of fire retardant impregnated into our plywood.

The Burnblock® method is certified by EPD® and Cradle to Cradle and is also VOC emission free.

Achieving the highest standards of fire safety must go hand in hand with environmental protection. This is why we use materials of the highest quality that are both human and environmentally friendly.

A key aspect is also the fire retardant treatment of the plywood under the control of an accredited certification body.

The plywood used in the fire retardant impregnation process is sourced only from proven, leading plywood manufacturers in the world, such as UPM (Finland), Latvijas Finieris (Latvia), SKLEJKA-MULTI S.A. (Poland), Sklejka-Eko S.A. (Poland), ESTPLY (Estonia).

After the fire retardant impregnation process, the plywood is dried to the moisture content required by the customer, usually 8-10%. The drying process takes place in an innovative dryer, which virtually eliminates deformation of the plywood.

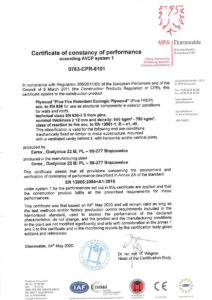

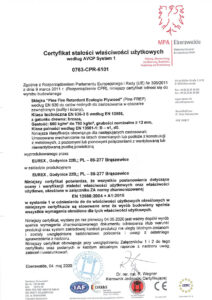

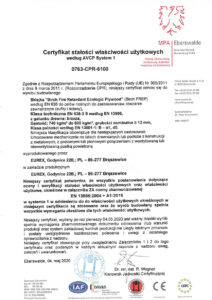

We are the holder of certificates

It should be added that the drying process takes place at low temperatures.

After fire retardant impregnation, fire retardant treatment and drying, the plywood goes to the next stage, which is sanding.

We have modern COSTA plywood sanders and a panel saw for cutting plywood and wood-based panels.

We also offer CNC machining as an optional service.

Costa S6 XCT 1350 sanding machine up to 1300 mm width.

Selco Sektor 350 panel saw up to a maximum plywood/panel size of 3800 x 3800 mm.