Thermally modified wood is produced by applying temperatures between 160 and 220°C under controlled low pressure conditions, without air and without the use of water. It is an environmentally friendly process as no chemicals are used. Thanks to the thermal treatment process, we can increase the durability class of the wood (for ash and larch we achieve the first class: more than 25 years of exposure to the weather). In addition, the wood acquires an attractive darker colour throughout the cross-section of the treated material, which facilitates further processing.

In 2023 we purchased a state-of-the-art chamber for the thermal treatment of wood.

We offer high quality thermo pine, thermo spruce and other thermally modified wood species. The entire range is from our own production. We rely on raw material (sawn timber) selected for the thermal treatment process. The raw material for thermally modified wood (sawn timber) is sourced exclusively from sawmills in Finland..

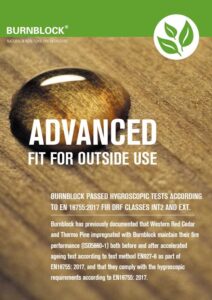

As an additional option we offer CE-certified FR (B-s1, d0)/NRO flame retardancy for all wood species after heat treatment.

The flame-retardant process is carried out using the vacuum-pressure method in an autoclave with the 100% non-toxic fire retardant Burnblock®.

FACADE BOARD

TERRACE BOARD

PLANED BOARD

We offer our customers the possibility to produce a profile according to individual wishes or the requirements of a specific project. In such cases we ask the customer to send us a technical drawing or a photo of the profile.

The minimum order for this option is 10 m3.

The minimum order for this option is 10 m3.

Product description

UV KOLOR PROTECTIVE OIL is an advanced preparation for the protection of wood against the destructive effects of UV rays. Thanks to its unique formula, the oil significantly prolongs the life of microporous wood coatings, providing them with long-lasting protection and aesthetic appearance.

Intended use

The product is ideal for the protection of vertical exterior wood surfaces such as:

Facades, cladding

- Facades, cladding

- Doors, windows and windowsills (dimensionally stable))

- Carports, fences, pergolas and gazebos (dimensionally unstable)

Functions and benefits

- Stand-alone coating: slows down the greying process of wood with a UV protection level of 12, providing significantly better protection than unprotected wood.

- Topcoat: can be applied over an existing pigment coating; extends the interval between necessary renovations

- Natural pigments: perfectly selected pigments balance the natural shade of the wood, giving it a beautiful, even shade

- Protection and smoothing: smoothes the surface of the wood, protecting it from water and dirt while allowing it to breathe freely

- Wood stability: reduces swelling and shrinkage of the wood – the material does not crack, peel or splinter

- To renovate an undamaged coating, clean thoroughly and apply one coat of UV Kolor protective oil every 2-3 years (depending on the degree of weathering).

- For surfaces exposed to particularly heavy weathering, such as facade cladding, window drip caps, post caps or window sills, more frequent coating renovation is required for effective wood preservation. Horizontal parts of horizontally installed wood surfaces should have a slope of at least 15 degrees. Sharp edges should be rounded to a radius of >2 mm.

- If the wood has started to show blue stains due to neglected renovation, the surface should be refreshed with Osmo wood grey stain remover gel and then two coats of UV Kolor protective oil should be applied.

- To achieve a coating with UV protection grade 12, two coats of UV Kolor protective oil are necessary. If only one coat of oil is applied to raw wood, the protective properties will be greatly reduced.

- Fresh wood rich in oily substances or particularly hard wood must be left to weather for about 6 weeks. This will make it more absorbent and allow the oil coating to bond with it in an optimal way.

- The final result will also depend on the characteristics of the wood, so it is advisable to test the product before applying it, especially if the substrate is unfamiliar.

If you buy a package, e.g. a facade board, a terrace board or a four side planed board after heat treatment from our production + OSMO, we give additional discounts on both the heat-treated wood and the OSMO products recommended for use on thermo pine, spruce, ash, ayous, poplar and frake/limba.

We have also started the production of garden architecture, including thermo pine:

GARDEN FURNITURE

FENCES

POTS

Our products guarantee the long-term and sustainable use of thermally treated wood in all possible markets and industries.

Properties of thermally treated wood:

Greater resistance to the effects of moisture, less water absorption; wood can be used outdoors without protection

Increased dimensional stability, significantly reduced deformation, warping or twisting of the wood

Improved thermal and acoustic insulation parameters

Increased resistance to fungi, bacteria and mould (change in wood durability class)

For coniferous wood species, heat treatment removes most of the resin and volatile substances.

Heat treatment changes the colour of the wood, giving it the appearance of exotic species.

Thermally treated timber is an environmentally friendly product and is completely safe for the environment and human health when used and disposed of.

Wood treated in our new chamber does not have an intense odour after treatment.

Heat-treated wood gains dimensional stability and does not work under the influence of moisture. All these features result in increased durability (durability class of the wood).

The appearance of the wood is reminiscent of exotic species, and it is all made from our native species!

The safe and environmentally friendly process of thermal treatment of wood is a growing market

Our treatment process requires no chemical additives, making the wood resistant to fungi, mould and pests.